Translucent concrete

- Translucent lightweight Concrete is anew material with various applications in the construction field,architecture, decoration and even in furniture industry. Intoday’s time where whole of the research isconcentrated towards non utilization of natural resources as much aspossible and toreduce its consumptionwhich are decreasing with time,Lightweight LiTraCon (Lightweight light transmitting concrete) is alightweight translucent concrete building material made of fine concrete embedded withup to5% by weightofconcrete mixwhich areimpregnated inside the concrete cubes so that light can be transmitted from theoutside in or inside out of the building. Due to great economic growth, urbanization, population growth, spaceutilization worldwide, there is drastic change in concrete technology. Most of the big buildings are built closeto each other all in the same areas like sky scrapers There arises one of biggest problem in deriving naturallight in building due obstruction of nearby structures. When buildings are stacks closed to eachother, there isnot much natural sunlight passing through it.A wall made of "Light LitraCon" has the strength of traditional concrete and an embedded array of glassrodsthat can display a view of the outside world. Thousands of optical glassrodsform amatrix and run parallel toeach other between the two main surfaces of every blocks where in which Shadows on the lighter side willappear with sharp outlines on the darker one. An opticalglassfibre is a flexible transparent fibre made ofglass (silica)or plastic, slightly thicker than a human hair & is a three layered cable made up of Buffercoating, cladding and core with transmits light through the core ofglass rods.

- Ordinary Portland Cement of 53 Grade. Manufactured Sand of pertaining Sieve size (<4.75mm) as per IS standards.

Methodology

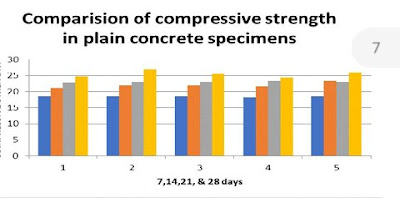

Preliminary tests were conducted on the normal conventional concrete materials as per IS standards &specifications for its physical & engineering properties, cubes were casted in the standard metallic moulds &vibrated to obtain the required sample size of specimen. The moulds were cleaned initially and oiled on all thesides before concrete sample is poured in to it. Thoroughly mixed concrete is poured into the moulds in threeequal layers and compacted using vibrating table for a small period of 5 minutes. The excess concrete isremoved out of the mould using trowel and the top surface is finished with smooth surface.The manufacturing process of transparent concrete is same as of the regular conventional concrete blocks withthe Only change isglass rodsare spread throughout the fine aggregate and cement mix & Small layers of theconcrete are poured on top of each other and infused with therodsin the wooden casted box. Lighttransmitting concrete is produced by adding 1%, 2%, 3%, 4% & 5% ofglass rodsbyweightinto the concretemixture, thetranslucent concrete mixture is made from fine aggregate materials only & does not containcoarse aggregates.Glass rodsand concrete are alternately inserted into moulds at an intervals of approximately1.5cmspacing&thecasted materials are cut into small panels or blocks of the specified thickness finally the surface istypically polished resulting in semi-gloss to high-gloss surface finish.After 24 hours the samples of both normal conventional concrete & translucent concrete were demoulded andput in curing tank for the respective periods of 7, 14, 21 and 28 days & a set of 5 samples were prepared foreach stage of curing. The temperature of curing tank was maintained about 25 degree during the analysis ofcharacteristic strength & the results were tabulated.

The main aim of the methodology is to-

To calculate the compressive strength of M25 grade plain concrete & translucent concrete by laboratory experiments as per IS specifications.

The main aim of the methodology is to-

To calculate the compressive strength of M25 grade plain concrete & translucent concrete by laboratory experiments as per IS specifications.

- To calculate the Split tensile strength of M25 grade plain concrete & translucent concrete by laboratoryexperiments as per IS specifications.

- To calculate the Flexural strength of M25 grade plain concrete & translucent concrete by laboratoryexperiments as per IS specifications

- Tests(physical properties) conducted on Concrete materials

- Test on cementFineness of cement.

- Normal Consistency of cement.

- Soundness test.Specific gravity.

- Initial setting time of cement.

- Final setting time of cement.

0 comments:

Post a Comment